Printer Calibration

Description

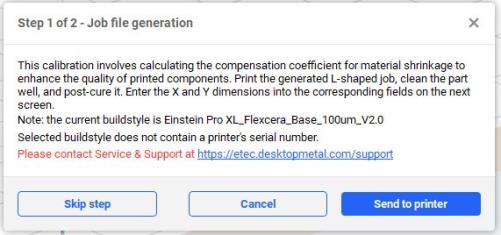

Calibration is a crucial step in the 3D printing process. It involves calculating the compensation coefficient for material shrinkage and saving it in the buildstyle file. By calibrating your 3D printer, you can compensate for the natural shrinkage of the material used for printing.

Procedure

1. Navigate to ![]() > Calibrate Printer.

> Calibrate Printer.

→ The system shows ‘Step 1’ of Shrinkage Compensation calibration with the name of the selected buildstyle.

2. Press Send to Printer.

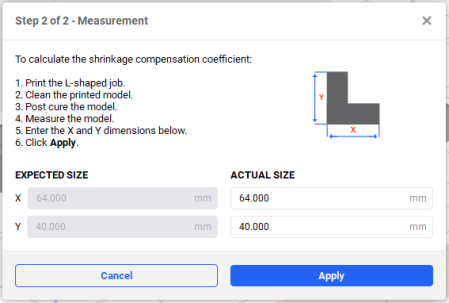

→ The following dialog box appears.

3. Print the L-shaped calibration job on the printer and clean it well.

4. Post-cure the printed part as required for the material.

5. Measure the model as shown in the picture in the dialog box above, see Tolerance List.

6. Enter the X and Y dimensions in the Actual Size input fields.

7. Press Apply.

→ The shrinkage calibration coefficient is saved in the buildstyle.

Tolerance List

| Printer | Tolerance, um | L-shaped Model Dimensions Range, mm |

| Einstein™ | 101 |

X: between 63.90 and 64.10 Y: between 39.90 and 40.10 |

| Einstein Pro XL™ | 92 |

X: Between 63.91 and 64.09 Y: Between 39.91 and 40.09 |