Main Printer Components, Starter Kit, and Accessories

Main Printer Components

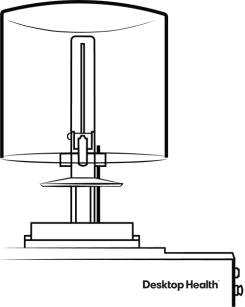

Hood

|

The orange hood protects the printer and the operator. It protects:

To open the hood, pull the hood lock on the rear side and then lift the hood upwards. The hood has a counterbalance cable that facilitates the upward movement of the hood and keeps it in position when open. |

|

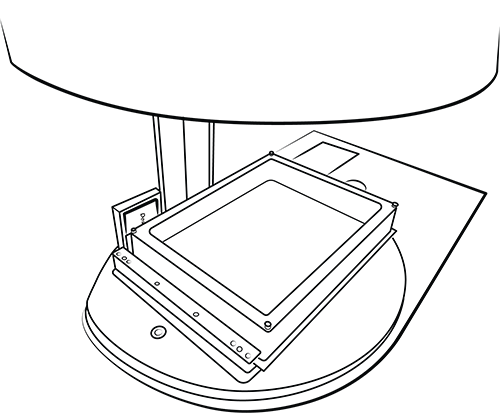

Build Platform

|

The build platform is an assembly comprised of:

The flat area of the build platform is where cured material will adhere during the printing process. |

|

Material Tray

|

The material tray consists of two frames with a special membrane called Pre-Stretched Assembly (PSA) between them, which fits snuggly over a piece of glass when installed on the printer. As the build platform moves up taking the exposed part away from the PSA, it pulls the membrane up finally releasing it and allowing the parts to separate. The build platform then moves back down and the next image in the sequence is projected; the cycle repeats itself. |

|

Z-Axis

|

The build platform moves up and down along the Z-axis. |

|

Emergency Stopping Devices

|

The printer is equipped with an emergency stopping device: a red emergency stop button. |

|

Starter Kit

Allen keys, 2mm, 2.5mm

|

Required for printer calibration and to assist with technical support cases. It is not required for day-to-day operation. |

|

Crossover network cable, 5mm, colored plug

| This cable connects the printer to the operating computer, as needed. The cable inserts into the I/O panel behind the printer. The other end plugs into the operating computer. |

|

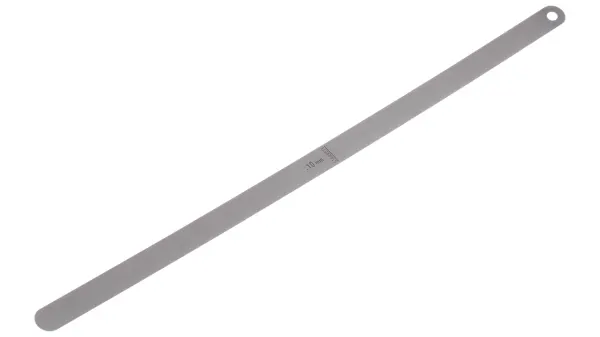

Feeler gauge, 0.15mm

| Required for printer calibration and to assist with technical support cases. It is not required for day-to-day operation. |

|

Grey filter foil

|

Required for light calibration and to assist with technical support cases. It is not required for day-to-day operation. |

Material mixing cards

|

Required to gently mix material in the material tray before each print. It is not required for day-to-day operation. |

|

Network cable, 5mm

|

This cable connects the printer to the local network. The cable inserts into the I/O panel behind the printer. The other end plugs into the network. The printer can be operated by other Windows computers on the network if the CAT 6 is plugged into a modem or into a network outlet. |

|

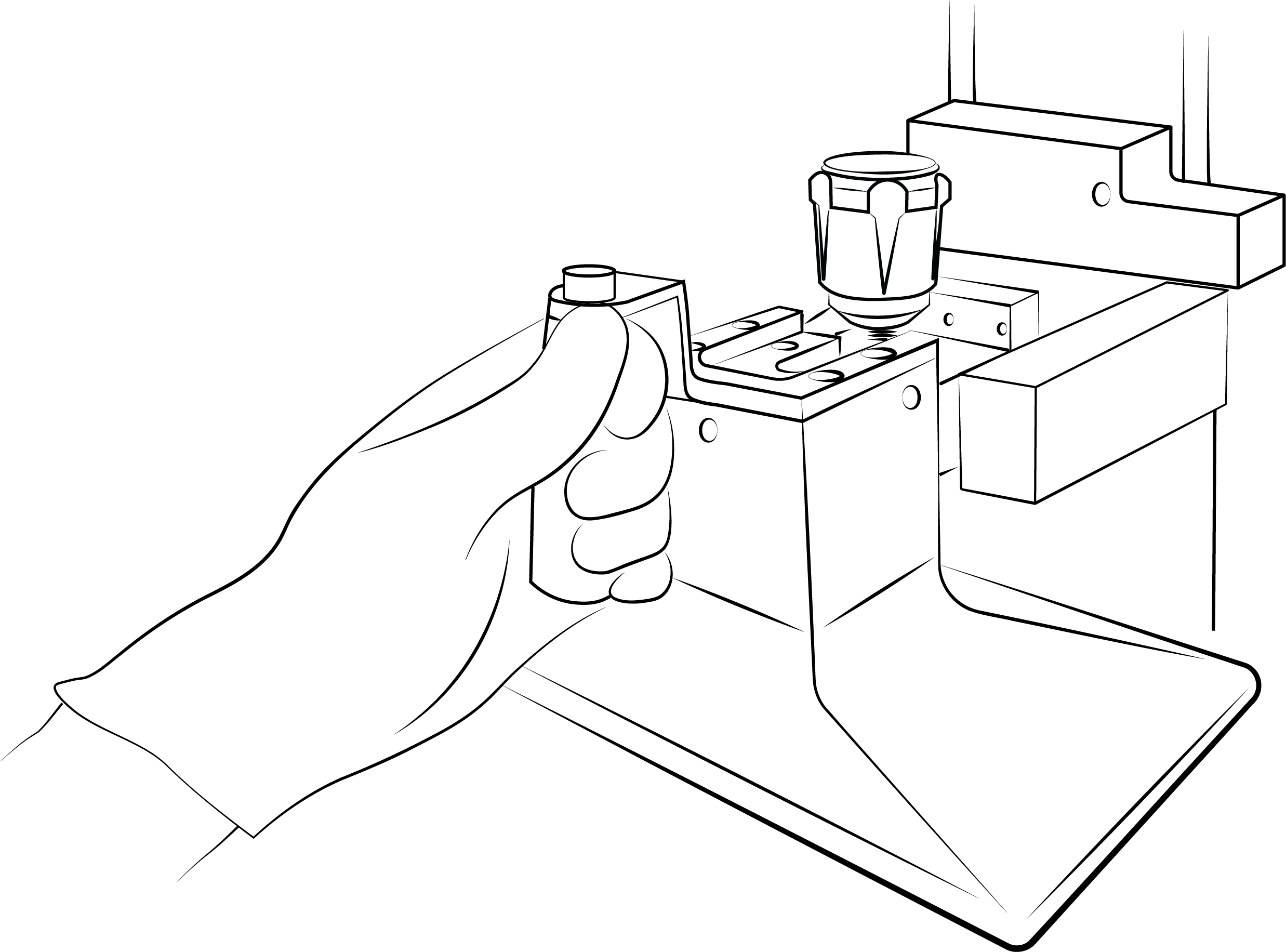

Paint Scraper

|

Use the scraper to Detach Printed Parts from Build Platform. Use the paint scraper for detaching larger printed models. You can also use the scraper to remove material residues from the build platform. |

USB drive

|

The USB is a back-up for transferring print information from the operating computer to the printer. Between 8 and 32 GB size is recommended. |

|

UV safety glasses

|

Required for light calibration and to assist with technical support cases. They are not required for day-to-day operation. |

|

Accessories

|

The PWA 2000 Parts Washing Apparatus is a convenient tool to assist in cleaning any uncured resin from 3D printed models. The convenient removable basket allows for ease of use when dipping or extracting objects from the tank. See Setup and Hardware Operations. |

|

|

|

|

|

The PCA 2000 Post Curing Unit is also available for non-medical materials printed with Einstein Pro XL. See Setup and Hardware Operations. |

|